Features

1. Time interval can be preset for automatic fill

2. Gentle liquid nitrogen flow, free of splashing or vibration

3. No direct contact with liquid nitrogen for safety

4. Full automatic control for easy operation

5. Low evaporation rate during standby

6. Can be connected to a computer for monitoring and data record

7. Compatible with Antech 35L ~ 120L liquid nitrogen dewar

Working principle

By heating liquid nitrogen in bottom of the dewar, an overpressure is built inside of dewar, to allow liquid nitrogen rise out of the pipeline and create a gentle liquid flow.

Filling time interval is adjustable, to match holdover time of detector. The filling flow is stable and gentle. As soon as the detector is full, the filling stops.

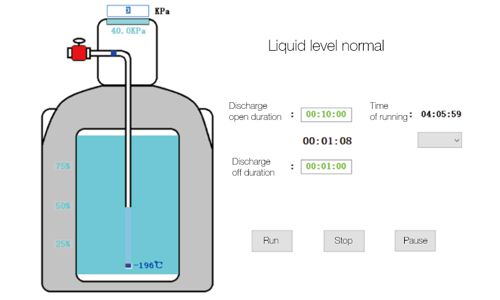

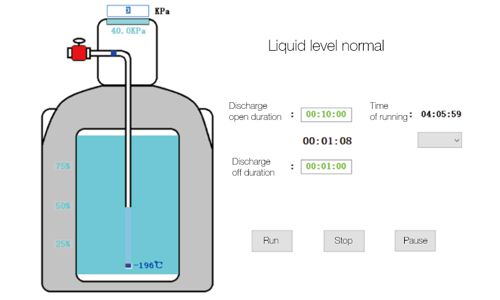

Controlling System

Touch screen controller on top of pump, displaying running statu s. All parameters can be set on touch screen,

which is convenient to use.

1.Temperature at bottom of container

2.Inner pressure

3.Time of discharging

4.Liquid nitrogen level

5.Number of circles

6.Setting

7.Power button

Control on PC

CryoPump 2000A is also supplied with controlling program for computer, to monitor its working status and make settings according to the demand.

Therefore, CryoPump 2000A offers the remote control without operater on site.